Who we are, today

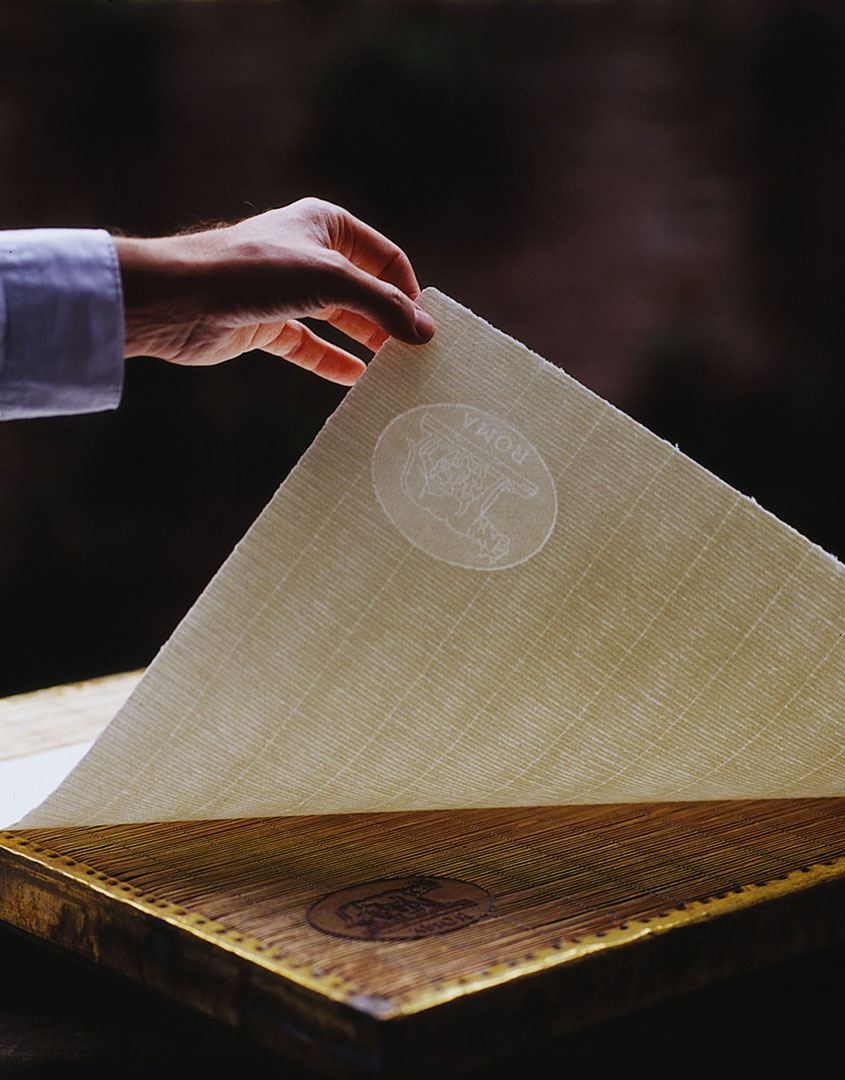

Fabriano is creativity. Fabriano is expression. Fabriano is white paper that gives space to your ideas.

Since 2002 Fabriano has been part of the Fedrigoni Group, a company specialising in the production and sale of special papers, from packaging to graphics, and premium solutions for the world of self-adhesives.

With more than 750 years of history, 4 production plants in Italy, more than 3000 catalogue products and distribution to over 100 countries, Fabriano paper is part of Italy’s cultural heritage and is chosen by millions of students and artists every year, in Italy and all over the world.

Our numbers

6

5000+

100+

Writing your story

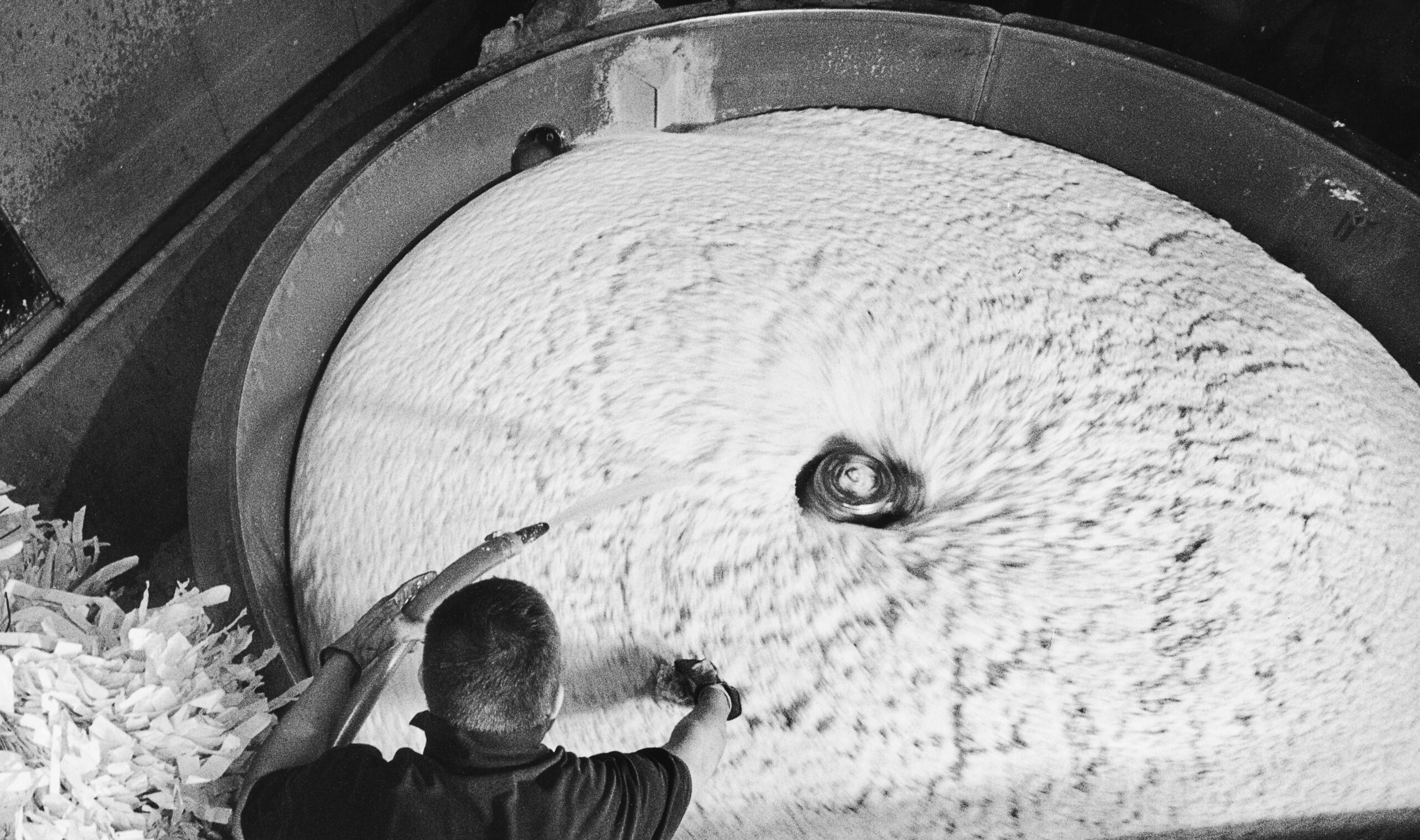

And with our hands sunk deep into a pulp of wet, cotton-fibre rags is how our story started, when artisan skills and business ethics were the result of ancient know-how handed down over the generations.

We have embraced the care and passion involved in producing unrivalled products in the world of paper, today and every day.

Since 1264 we’ve been writing our story whilst telling thousands of others: your stories