The story of paper begins in Asia along the Silk Road, arriving in Fabriano. Back in 1264, it was here that the ingenious concept of cotton fibre paper emerged, a stroke of genius during the medieval period, with the entire process proudly Made in Italy.

Fabriano is renowned for three significant breakthroughs: animal gelatine, the watermark, and the multiple hammer mill. Equally important are the three unique manufacturing methods that continue to set its paper apart: handmade, mould-made machine, and Fourdrinier machine.

Paper making

The 3 Fabriano Innovations

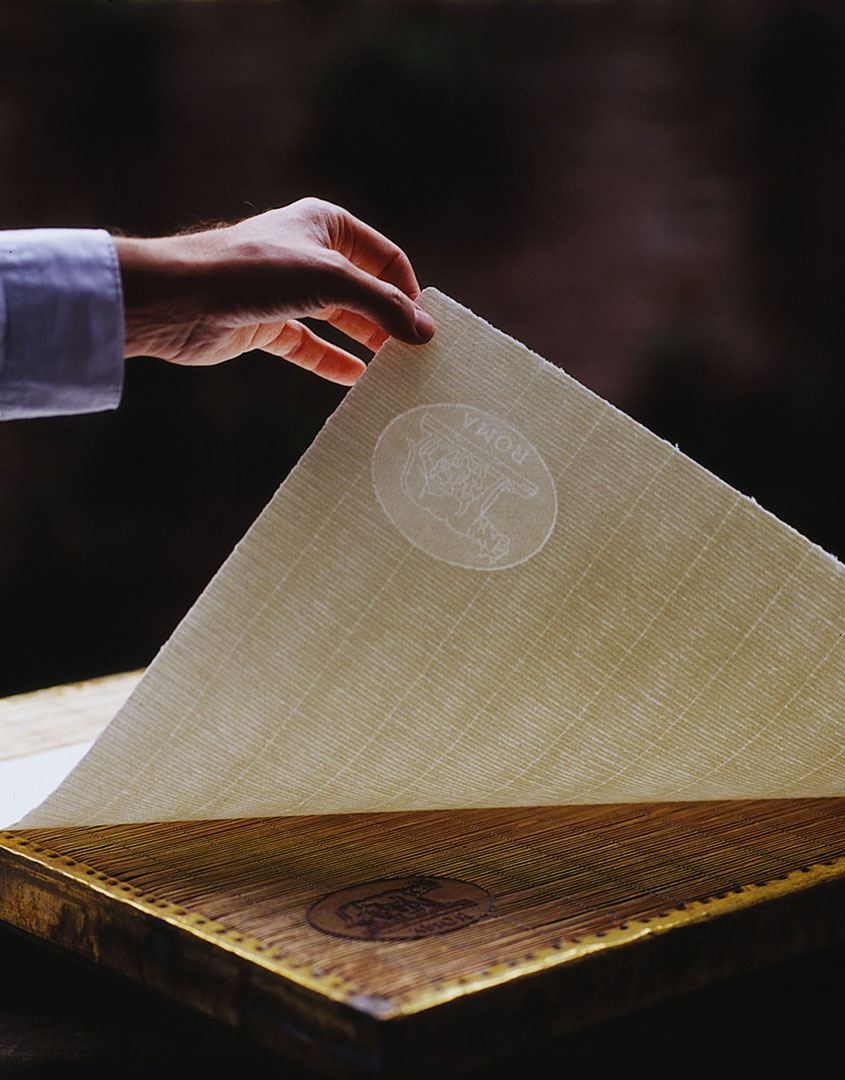

Watermark

A watermark is a design, text, or pattern that reveals itself when you hold a piece of paper up to the light. This exceptional invention of the master papermakers from Fabriano has been globally recognised and valued since the 13th century. It started as a craftsman’s mark in small workshops and evolved into a sophisticated anti-counterfeiting measure.

Animal Gelatine

This type of gelatine is derived from boiling down the remnants from the leather tanning process. It’s a crucial ingredient for paper sizing, a technique to waterproof the paper, ensuring it doesn’t absorb ink. This innovation was pivotal in the history of paper, as it allowed for its use in official documents, offering a greater degree of ink resistance and durability.

Multiple hammer mill

A traditional apparatus in the craft of handmade paper production. Initially featuring a single pounding mechanism, the evolution to include multiple hammers on a single device enabled various processes to be carried out simultaneously. This advancement significantly improved the paper’s quality and increased production efficiency with specific actions like thinning out, refining, and surfacing.

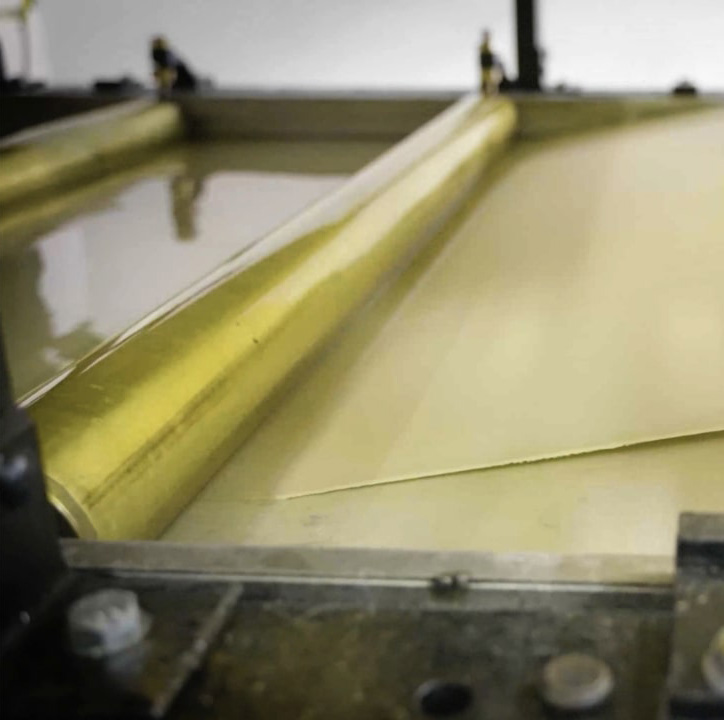

Production processes

In Fabriano, there are three main production processes: handmade, mould-made machine, and Fourdrinier machine.

Explore the enduring craft of handmade paper, where each stage of the process is a testament to the eight-hundred-year legacy of Fabriano’s master papermakers.